High voltage maintenance

Other the past 18 months we have carried out high voltage maintenance on over 20 different wind farms, and we have used this experience to develop our wind farm HV asset management system.

We feel strongly that high voltage maintenance should be planned on a scientific basis, with efforts concentrated on the equipment that is likely to fail and have a big impact on safety or reliability. Our engineer Richard Horan was previously responsible for the reliability of power supplies to the London Underground, and understands the three way balance between safety, reliability and cost. All maintenance is also carried out and documented to ensure minimum legal requirements are met, which includes maintenance of an asset database.

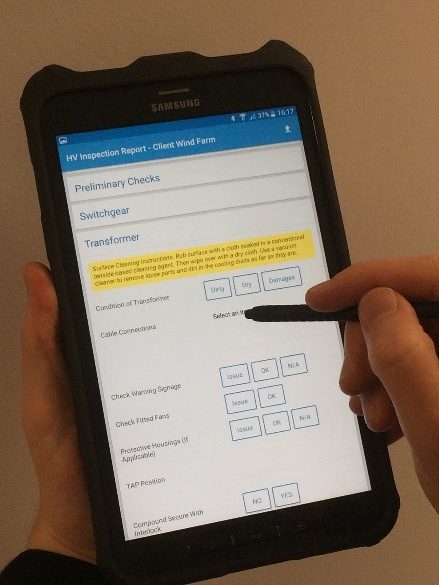

We have developed a tablet based data capture system to drive our high voltage maintenance. This data is fed back into an asset management database in real time, and allows us to determine failure trends. This allows us to carry a stock of spares for the most unreliable and most critical components. The asset management system also allows quick and easy reporting on overall reliability data for a clients assets. Clients also have full access to the maintenance data, with the ability to drill down into the data behind individual equipment failures. In wind farm operations the availability is key, and we aim to programme high voltage maintenance to coincide with general turbine maintenance and maintain a high availability for the wind farm.